One of my two main Ravelympics projects is a dyeing project I've been planning for a while. Noel and I are huge fans of the BBC archaeology program Time Team, featuring Prof. Mick Aston and his incredible rainbow sweaters. Seriously, whenever one of us finds some random piece of history while digging in the garden we like to pretend we've found some iron age pottery or a Roman villa or something. Anyway, I was very impressed by Mick's obviously handmade sweaters from the start. Then Noel asked me to knit him one. Of course I spent days and weeks trying to find a yarn that came in the right variations of colours, without much success.

I finally decided to use some of my masses of undyed worsted-weight yarn and dye it up in the colours I want. I won't get them right on what Mick has, but I do hope to get close. And I have just three days to do it. (It wouldn't be the Ravelmpics without a challenge like that.)

Technorati Tags: crafts, dyeing, ravelympics 2010, yarn

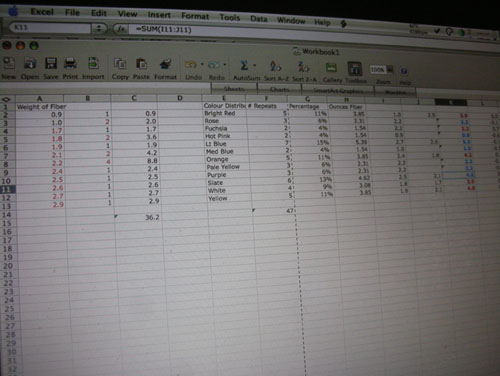

I spent time before the Olympics began dividing the yarn up into smaller skeins (it came in massive 1/2-kilo skeins). Yesterday I weighed those skeins and divided them up by size.

Using photos of Mick's sweater (like the one above), I figured out the number of colours in the sweater plus their distribution in the sweater. I made a spreadsheet to figure out how much of the yarn I needed to use for each colour, and then used a brute force method to decide which skeins would be dyed which colours.

Rather than risk getting dye on my laptop, I noted the weights of the skeins for each colour on my notes.

I arranged the yarn according to my notes, so I could easily find the skeins I wanted as I began a batch of dyeing. The key to large projects like this is to do as much mise en place as possible before you get started, so you don't find yourself making dumb mistakes, or running all over the house looking for gloves or a thermometer while overcooking your yarn on the stove.

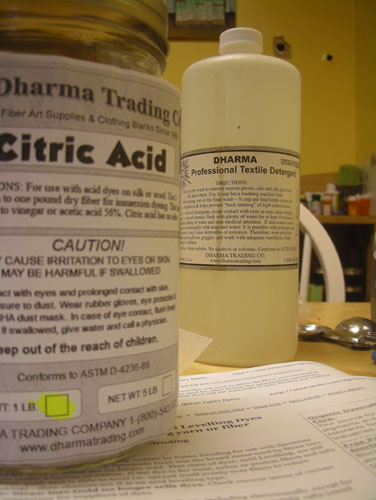

I decided to start with bright red, since that is one of the easier colours to get. I began by soaking the yarn in warm water with a little detergent (I used Dharma Trading's Synthropol substitute, called Professional Textile Detergent). The detergent acts as a wetting agent to help get the yarn good and soaked, and it doesn't need to be washed out because it is neutral in this application.

I filled up a dye pot (I bought some cheap stock pots for the purpose, since they cannot be reused for food) with warm water. I mixed my weighed dye powder with a little warm water, stirred it smooth, and added it to the pot. Then I dropped in the yarn and stirred it around. I let that soak for about ten minutes, so the dye could distribute evenly through the yarn.

Then I gradually brought the temperature up to about 120F. At that point, I mixed citric acid crystals (1 Tbsp per pound of fiber, which was 1/4 Tbsp in this case, not an easy measurement, but it didn't need to be super precise) in hot-hot water, then poured that solution into the pot and stirred it in well (but not vigorously).

I used citric acid because it smells better than the white vinegar that is the cheap/low-tech way to acidify the dye. I don't mind the vinegar smell too much, but I'm going to be dyeing for several afternoons, so I decided to spring for the less smelly version. Dharma Trading, just up the bay in San Rafael, is a great source for dyeing stuff, and I'd gotten a one-pound bag of crystals the last time I was there.

I had a selection of acid dye powders to choose from. I used cherry red for my first batch of yarn, then pink to get the range of pinks, then turquoise to get a light blue.

It took nearly an hour to get the temperature in the dye pot up to 180F, which is the temperature at which the dye sets. I didn't rush it: just kept the heat low, stirred every ten or so minutes very gently, and checked it often.

Once the temperature was at the right point, the dye was also exhausted from the dye pot. You can see here that the water is clear, rather than coloured. All the dye is now bound to the wool.

Then I let the dye pot cool down. Just turned off the heat and let it sit for another hour or more. Then I rinsed the yarn with hot water (the water in the pot was still quite hot), and put it in the dryer (I have a rack for drying delicates in my dryer; otherwise I would have hung it up to dry).

I was quite happy with the colour, The red came out exactly as I wanted.

And because I'm going to begin knitting with it relatively soon, I balled up the skeins as I finished them. I got bright red, two shades of pink (I was going to do three but decided to make the pale pink a brighter pink for this sweater), and the turquoise (which came out too bright) done in the first round of dyeing.

And we had only one mishap, when Mr. Kitty stuck his paw in a cup of dye solution that I was letting dissolve on the counter (that cat gets into everything). He turned a little blue and got little blue footprints everywhere, but seems none the worse for wear.